The NADCA Tabletop Exposition was held in Louisville, Kentucky from September 16-18, 2013. The Exposition was a large success with over 750 attendees visiting with suppliers and their peers.

A well known event during the exposition was the 2013 International Die Casting Design Competition which acknowledges industry innovation along with promoting the increased use of die castings through recognizing and publicizing outstanding designs. There are four equally weighted criteria: ingenuity of casting and/or product design, overall quality, cost savings as compared to other manufacturing processes and the part’s contribution to expanding the market for die castings. A panel of independent judges—acknowledged experts—chose this year’s winners.

There are a number of different categories in the International Design Competition and the winner in the “Aluminum Die Casting over 10 lb.” was Microcast Technologies, Linden, NJ.

As President of MicroCast Technologies (in addition to being President of Premier), I had the honor of being present during the Award Presentation by Steve Uvardy, Technical Director of NADCA.

Also attending the Awards Presentation was Owen VandeVelde, Product Design Engineer for our customer Acceleroptics (a division of H.E. Williams) and Edward Wasowski, Engineering Manager of MicroCast Technologies. Owen and Ed were instrumental in designing a Roadway Housing for an LED Light fixture that runs in an 1100 ton aluminum die casting machine and weighs 15.8 lbs.

This award-winning die casting incorporates all of the LED mounting, access and maintenance features in a single die casting, thus lowering the total system cost and providing for long maintenance-free operations of the fixture.

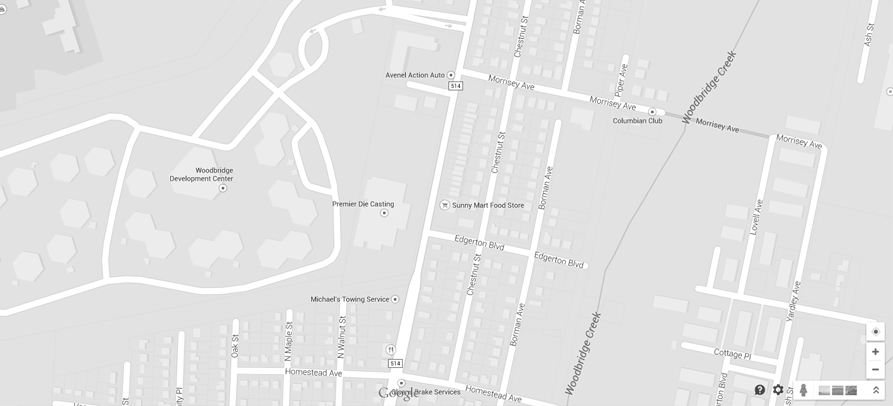

MicroCast Technologies, located in Linden, NJ, specializes in aluminum and zinc die casting, machining, assembly and plating services for the military, telecommunications and LED lighting industries.

Premier Engineered Products has been in business 68 years and has a diverse customer base that serves many industries and markets.

Premier utilizes state of the art equipment in manufacturing high pressure aluminum die castings such as robots, computerized process monitoring, die temperature control systems, and late model CNC machine centers that machine the castings produced to exacting dimensions.

Please send your inquiries and project files to sales@diecasting.com

By Leonard Cordaro, President of Premier Engineered Products